We accomplished a ‘Concrete Pour Win’ at NGC’s Holiday Inn Express project, located in Downtown Lincoln at 9th & O Street. The success is fully attributed to great preparation, communication and teamwork! Here’s the how NGC accomplishes such an amazing feat: Months before the pour, there is immense planning.

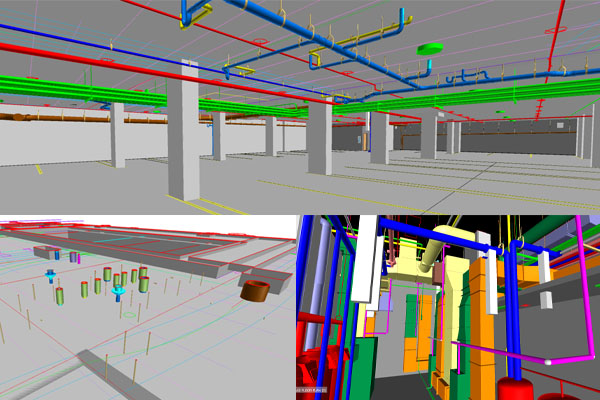

This project utilized a BIM process bringing in structural, mechanical, plumbing, and electrical trades to not only determine clashes, but also layout the deck. We installed “blue banger hanger” inserts in the deck which allows subcontractors to install their work after the deck is poured, preventing any need to post drill into the deck. Shop drawings were made available to our trades, so crews could pre-fabricate their systems which, in turn, helped speed up the schedule. Along with the inserts, we had MEP embeds, sleeves, hold-down anchors, anchor bolts, structural steel embeds, stud rails, reinforcing steel, and PT (post-tension) tendons.

Over 4,000 points on the deck were laid out using a surveying system–no need for pulling a tape! This clash-detection software helps us achieve precision work and avoids any conflict; Hold-down anchors, MEP sleeves, electrical boxes are all placed in the slab in relation with the wall layout and other components.

We are able to stress the slab within one to two days after the pour because we use maturity meters to determine the strength of the concrete rather than waiting to receive a concrete cylinder break test typically used with traditional concrete placing methods. Once the maturity meters show 75% strength, we’re able to tension the tendons.

See the BIM captures below and the photo collage of the pre-pour, the two pumps, the adept crew members screeding, floating and finishing the concrete, as well as the multiple mixers tag-teaming on deck on our adjacent lot.

Please get in touch with us regarding this project, strategic concrete pours or to connect with NGC field leaders. Thank you!